pen with adjustable diameter

[trinity]

2019 | Individual project

Duration: 3 months

The “trinity” concept is a writing instrument whose diameter can be adjusted to three different sizes. This feature allows the pen to be used for different creative tasks that have distinct ergonomic requirements. The concept is developed in the form of a universal ballpoint pen.

Different pens for different tasks

The design of trinity emerged from an intensive examination of the various uses of writing instruments. In the process, it became apparent that pens used for different purposes also differ in shape and size. For example, narrow pens are often used for precise sketching because they offer better control. For writing longer texts by hand, however, pens with a larger diameter are more suitable, as they are easier to hold and thus prevent the hand from tiring quickly.

Besides the type of use, the required pen diameter also depends on the size of the user's hand.

Constructed for adjustability

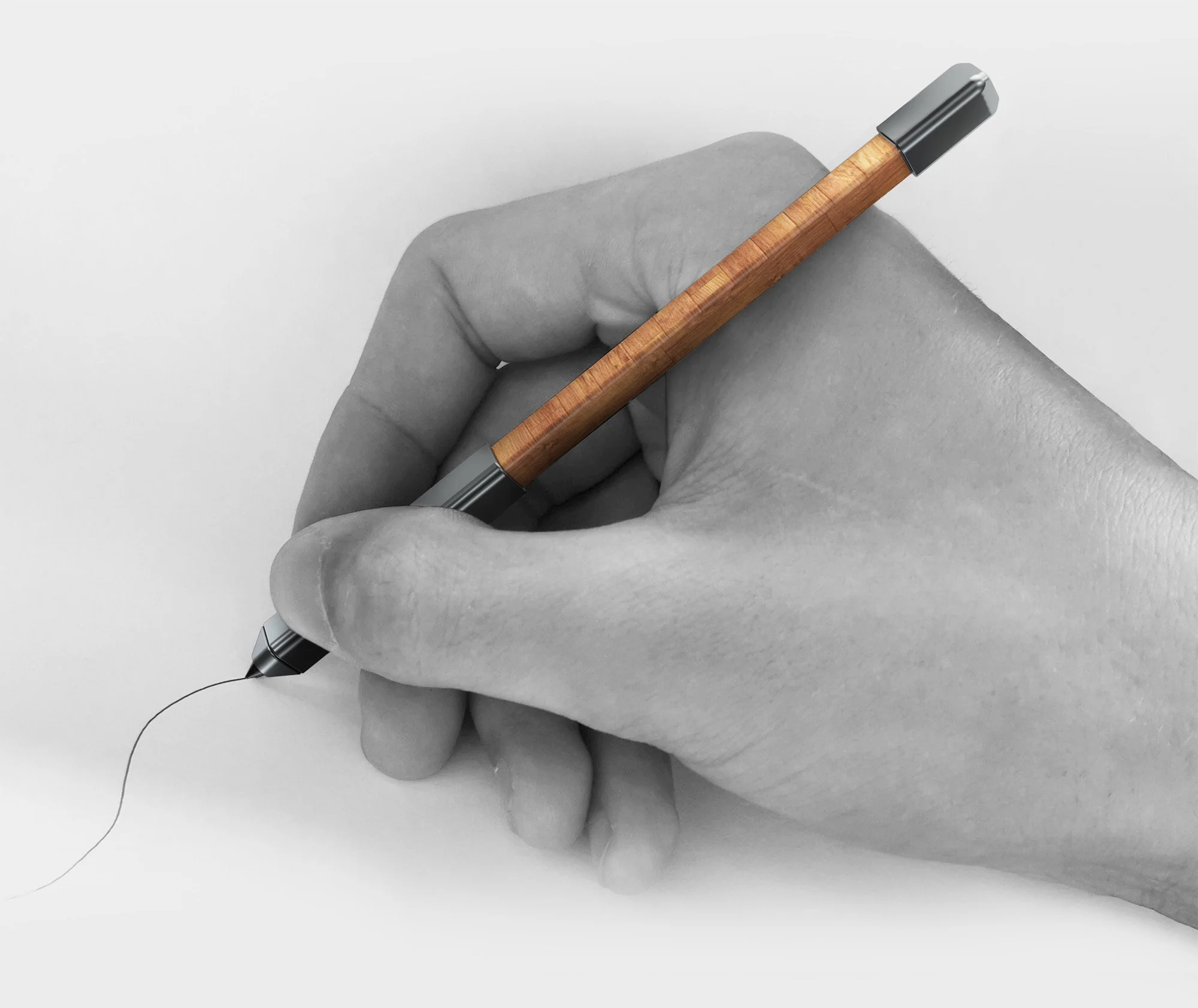

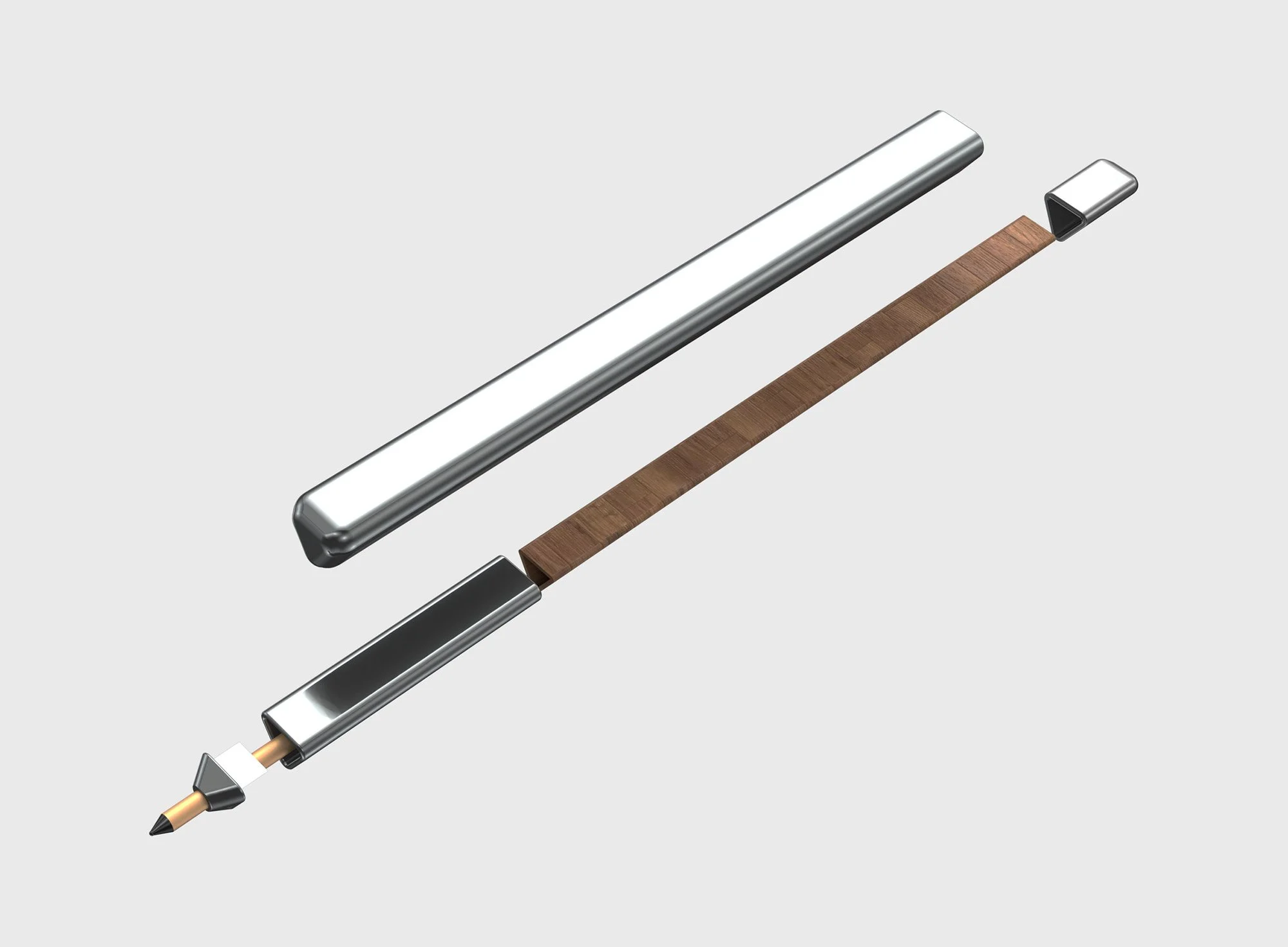

The designed writing instrument consists of a wooden body whose diameter can be adjusted in two stages by moving a sleeve between two positions. A third diameter variant can be set by placing the cap of the pen on its upper side. By doing so, the diameter of the writing instrument can be adjusted in 2 mm increments.

Matching its name, the “trinity” pen design has a triangular cross-section. This shape provides a good grip on the pen, as all fingers used for holding it can fit comfortably, while the edges of the triangular shape prevent the pen from twisting in the hand.

The pen is made of individual stainless steel parts and laminated wood which are pressed together. This manufacturing method offers the advantage that the pen can be produced quickly, but can also be completely disassembled at the end of its lifespan. This makes it possible to separate and recycle all the materials used.

Design process

The aim of the concept was to combine three pens for different uses in one product. In order to find the right shape for each type of use, a series of handle models were produced. These models were made from turned wood. Partly, the models were coated with rubber.

Functional prototypes were 3D-printed to verify the results of the ergonomic studies and review the overall concept.