bentwood interior modules

2022 | Individual project

Duration: 4 months

Cooperation: Weitzer Parkett

Developed in collaboration with Weitzer Parkett, this project investigates how structures made of wood can be created with minimal use of materials while still offering a high level of stability.

This approach resulted in a system of bentwood modules that can be used to furnish interior spaces. Combining these modules creates room dividers, seating, and other functional furniture.

A flexible furniture system for changing housing situations

Nowadays, people often move and change their living spaces. This causes changes in the requirements for furnishing their homes. To solve this problem the developed system offers universal building blocks that allow people to adapt the interior design of their homes to their own needs.

To create pieces of furniture, the modules are connected. When they are no longer needed, they can be separated and reused for other purposes.

The project shows how the concept of modular parquet flooring can be expanded to a new dimension, allowing living situations to be changed in a simple and sustainable way.

The system consists of modules measuring 200 x 200 x 125 mm. They are connected with screw elements that can be fastened and loosened without tools.

Modular construction

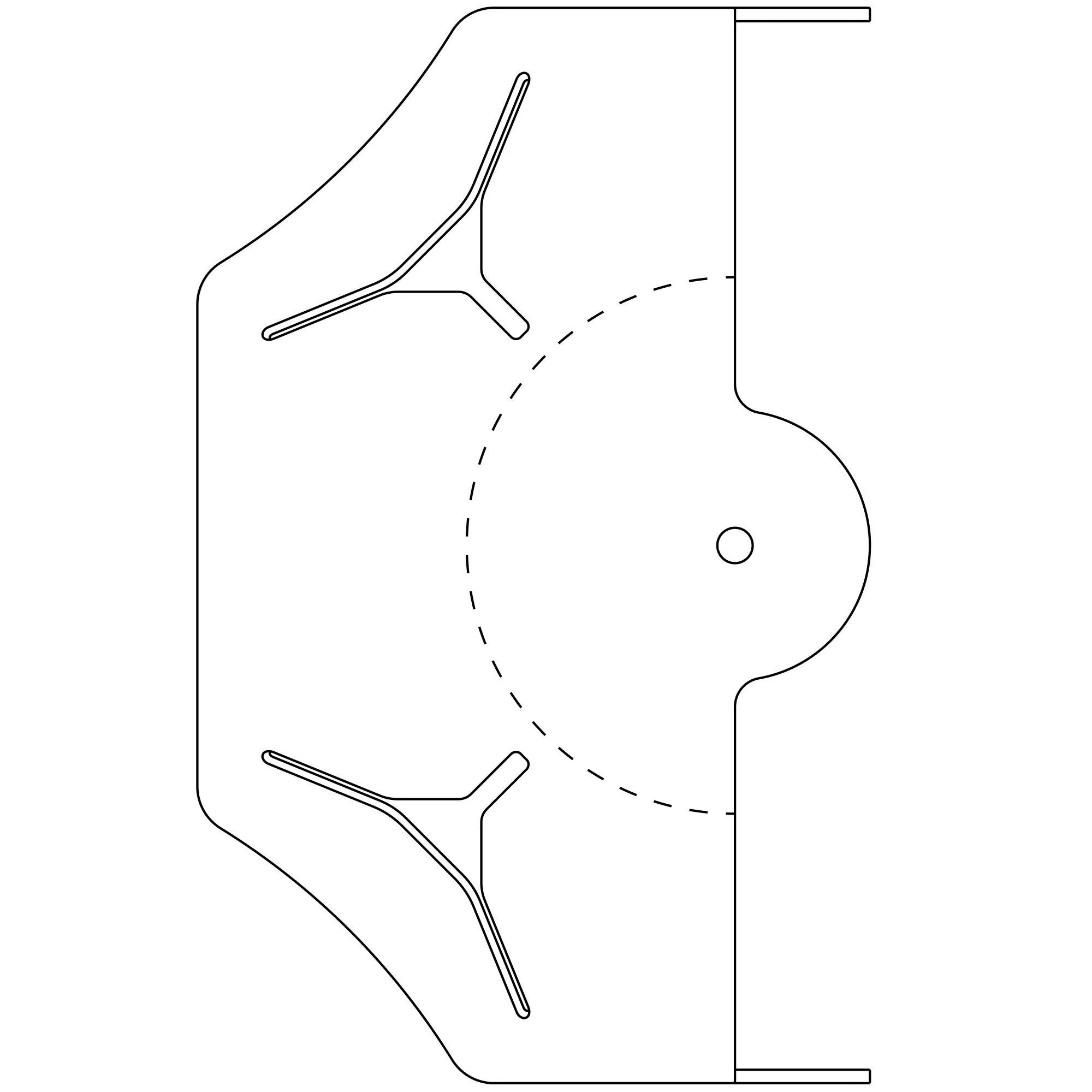

Single wood module – front view

Single wood module – side view

To produce the wooden modules, strips of veneer are pressed between a positive and negative mold with the addition of a sustainable glue. To increase strength, the surfaces of the modules are curved. This manufacturing method was tested on a smaller scale with veneer strips.

Experiment on the production of curved bentwood using a 3D-printed mold.

Step 1 – Molding process: Applying adhesive to wooden veneer

Step 2 – Molding process: The veneer is laid into the mold

Step 3 – Molding process: The half molds get pressed together

In the design process, a wide range of repeating shapes were explored that could be joined together to form larger volumes.

Design process

Another point that was covered in the development of the design was creating structural strength in thin, plate-shaped materials, which is possible using folding techniques.

Paper modules that are folded into a load-bearing, three-dimensional shape and can be connected to each other.

Experiment with linking rigid panels with hinges to form a foldable structure