system for a shared vacuum cleaner [ami temporaire]

2025 | Master’s thesis

Duration: 10 months

Individual project

Ami Temporaire was developed to explore how the design of household appliances needs to be adapted to be used successfully in rental concepts. The concept was developed using a battery-powered hand vacuum cleaner as an example.

The device developed in this process is easy to service, as all components are removable, and can be adapted to different types of use by swapping out functional modules.

Users can adapt the vacuum cleaner to their needs by using different function modules.

The vacuum cleaner is optimized for compact shipping and can be separated into parts for this purpose.

The goal: reducing the environmental impact of household appliances

E-waste is a major ecological problem, and disposed household appliances play a large part in this. One solution is to extend the lifespan of household appliances in order to reduce their negative ecological impact.

As an approach to achieve this, the “ami temporaire” concept shows how access to durable household appliances and their repairs can be provided through a rental service and how appliances need to be designed to be usable in this kind of system.

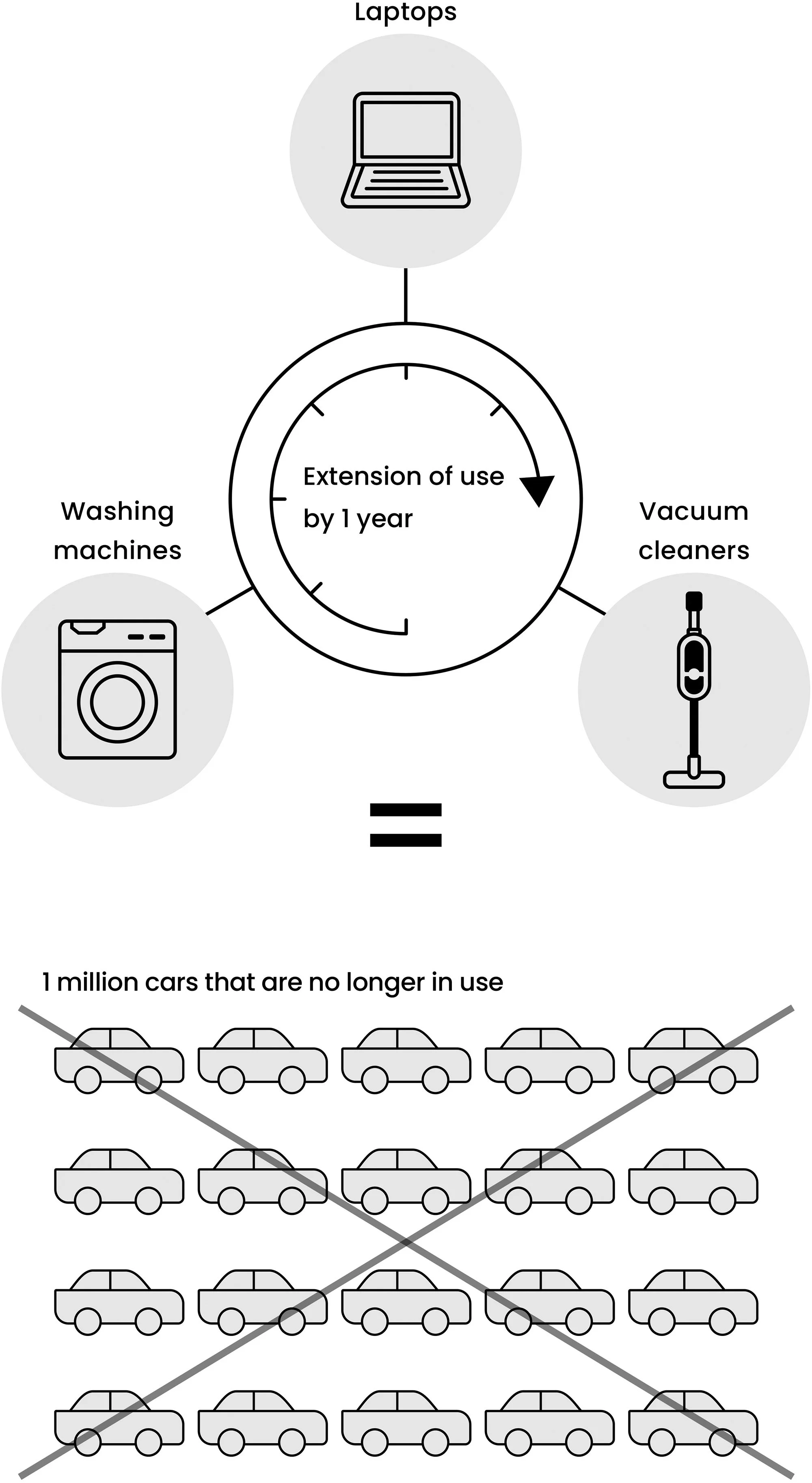

Environmental effects of an extended period of use for electrical appliances vs. a reduction in the number of cars used over a ten-year timeframe in the EU.

Source: Coolproducts don’t cost the earth - full report

Design of a vacuum cleaner for shared use in rental services

For cleaning different surfaces, the vacuum cleaner can be adapted by changing the attachments and adjusting the length of the suction tube.

The vacuum cleaner is made available via a service and refurbished between use cycles. Therefore, it is equipped with screw connections so that components can be easily replaced.

To allow the vacuum cleaner to be customized to different requirements, it is built from functional modules that are mechanically and electrically connected using a plug-in system.

ABS and PP plastics are used for the structural components as unmixed materials, allowing them to be recycled without any loss of quality. Stainless steel and recycled plastic are also used.

The external elements can be easily swapped out. This allows the users to choose between different material variants. To ensure that the housing can also be produced by third-party suppliers, the shape was designed to be as simple as possible.

Customizable structure consisting of interchangeable modules

Base and dust container

Battery module

Cable reel module

Vacuum nozzles

Packaging with a small volume for efficient shipping

The outer packaging is made of waxed cardboard with air cushions and protects the vacuum cleaner from damage and moisture. Its dimensions are 690 x 210 x 150 mm.

Inside the packaging, an inlay holds the modules in place.

If the packaging is no longer needed, it can be folded down to letter size and returned for reuse.

Storage system

The storage stand is part of the system. It is used to store the vacuum cleaner conveniently and provides space for the accessories.

To ensure that the system can be packed compactly for shipping, the stand can be completely disassembled.

Design process

The foundation for the design process was the analysis of existing vacuum cleaners and the different ways in which vacuum cleaners are used.

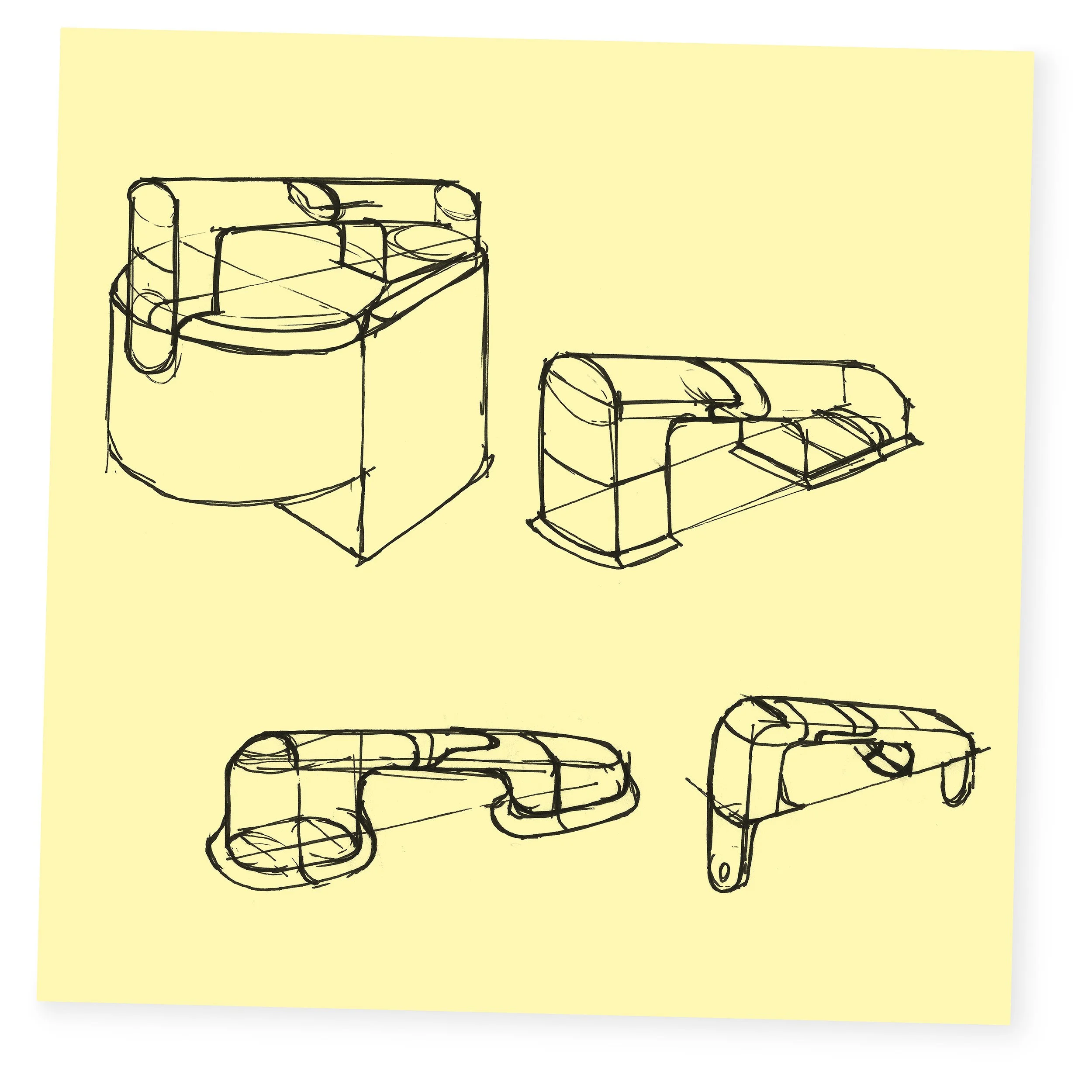

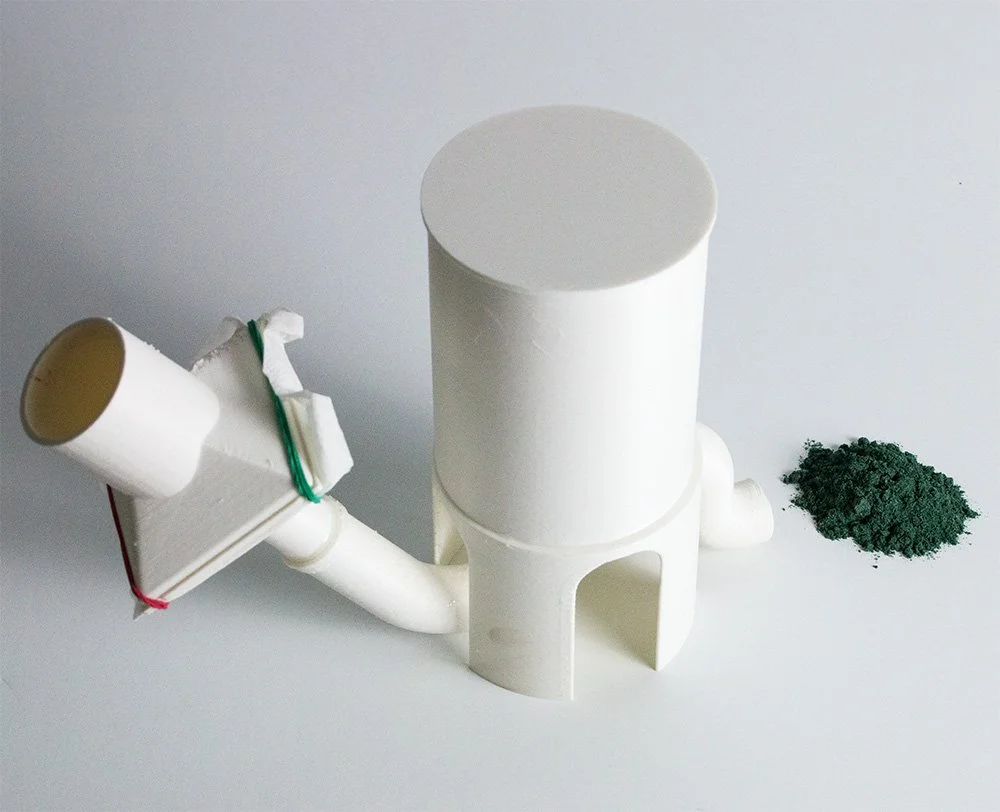

The information collected from the product and user analysis was used to create sketches and models. The models were built in full scale. They were used to test the ergonomics and the user interface of the vacuum cleaner.

A cyclone filter is used in the vacuum cleaner to extract the dirt from the sucked-in air. In order to find the optimum shape for this, smaller filter models were built that could be connected to a conventional vacuum cleaner for testing.