vending machine for unpackaged groceries

2021 | Bachelor's thesis

Duration: 6 months

Individual project

This vending machine concept is the result of my bachelor's thesis. It's designed to sell foods like tofu or cheese, which need to be kept cool and require specific hygiene conditions, without the need for packaging.

The vending machine is intended for use in zero-waste shops. There, it makes it possible to offer foods that were previously only sold in packaging without the need for it, thereby reducing the amount of wrapping waste generated by food.

Reduction of packaging waste from foods through a adapted sales concept

Food dispenser for dry foods in a zero-waste shop

Sale of dairy products and tofu in a zero-waste shop using glass containers

A large part of the packaging waste generated by private individuals in Germany comes from food packaging waste. This means that food contributes to various environmental problems even after it has been consumed. One approach to reducing this problem is to offer food in specialized stores where food is sold without packaging and can be filled into reusable packaging brought by shoppers.

These stores already sell food that is dry and requires no refrigeration. Soy and milk products that need to be refrigerated are still rarely sold. This is because ensuring hygiene and protecting these foods from contamination can only be guaranteed with great effort, which is difficult for small shops to implement.

The concept of a food vending machine reduces this workload for operators of zero-waste shops by creating a hygienically safe environment for sensitive foods with minimal effort.

A vending machine that lightens the workload in zero-waste shops

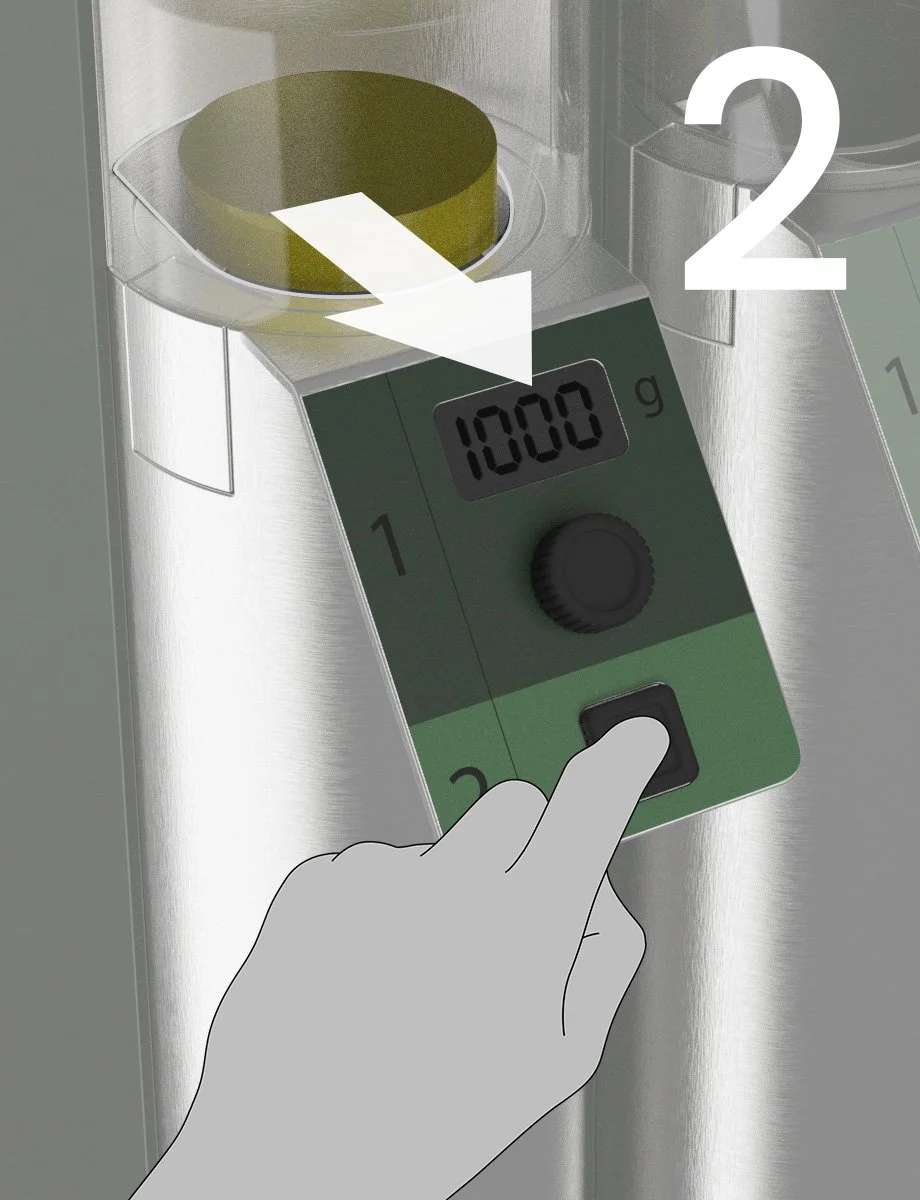

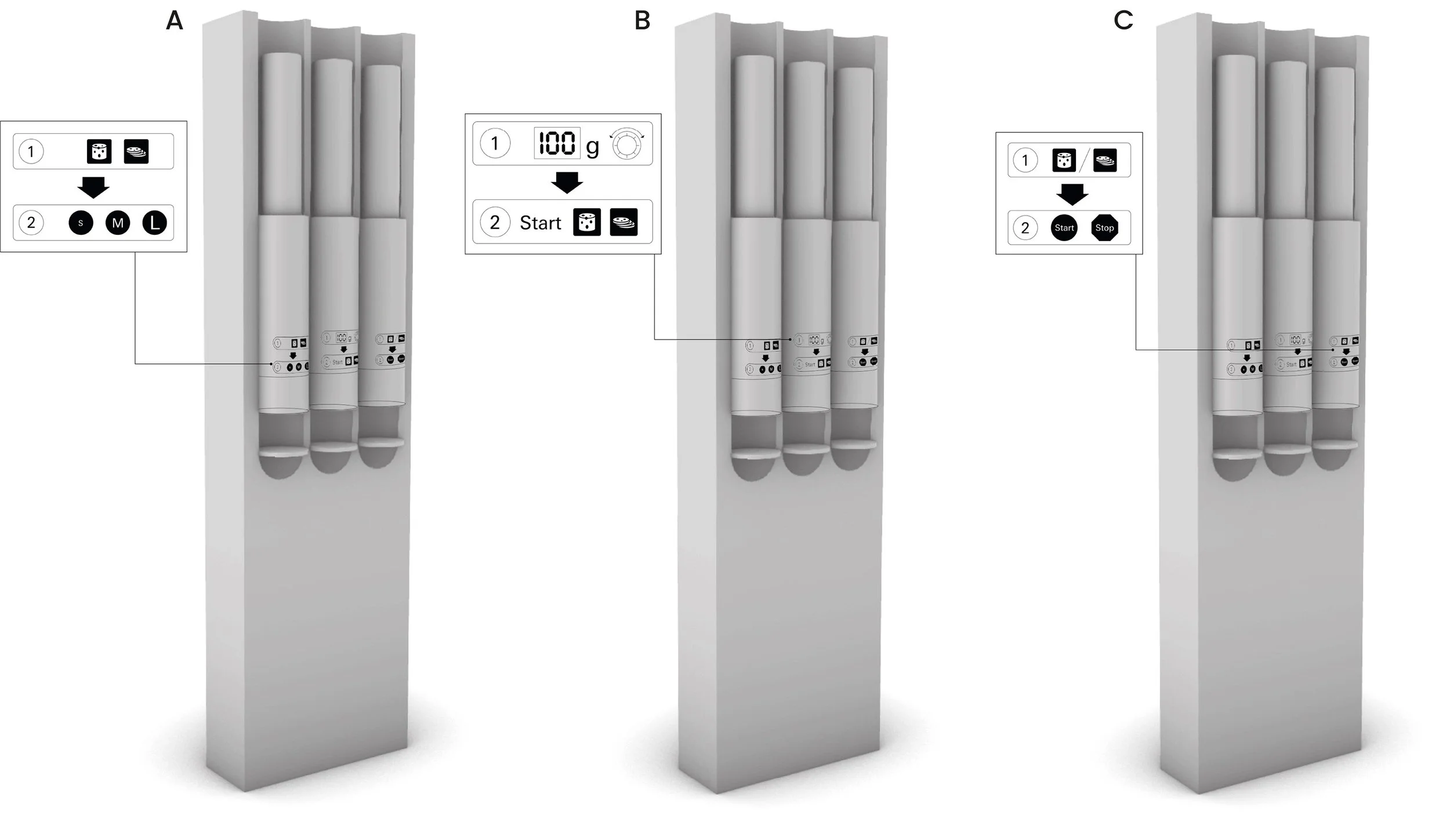

The designed vending machine simplifies work in zero-waste shops by taking on the task of portioning food and ensuring its correct storage. For this purpose, the sold food is delivered in reusable containers and placed in the machine. The desired food and quantity can be selected via a user interface. After that the selected quantity gets separated and can be removed by the buyers, while the food remaining in the vending machine remains covered.

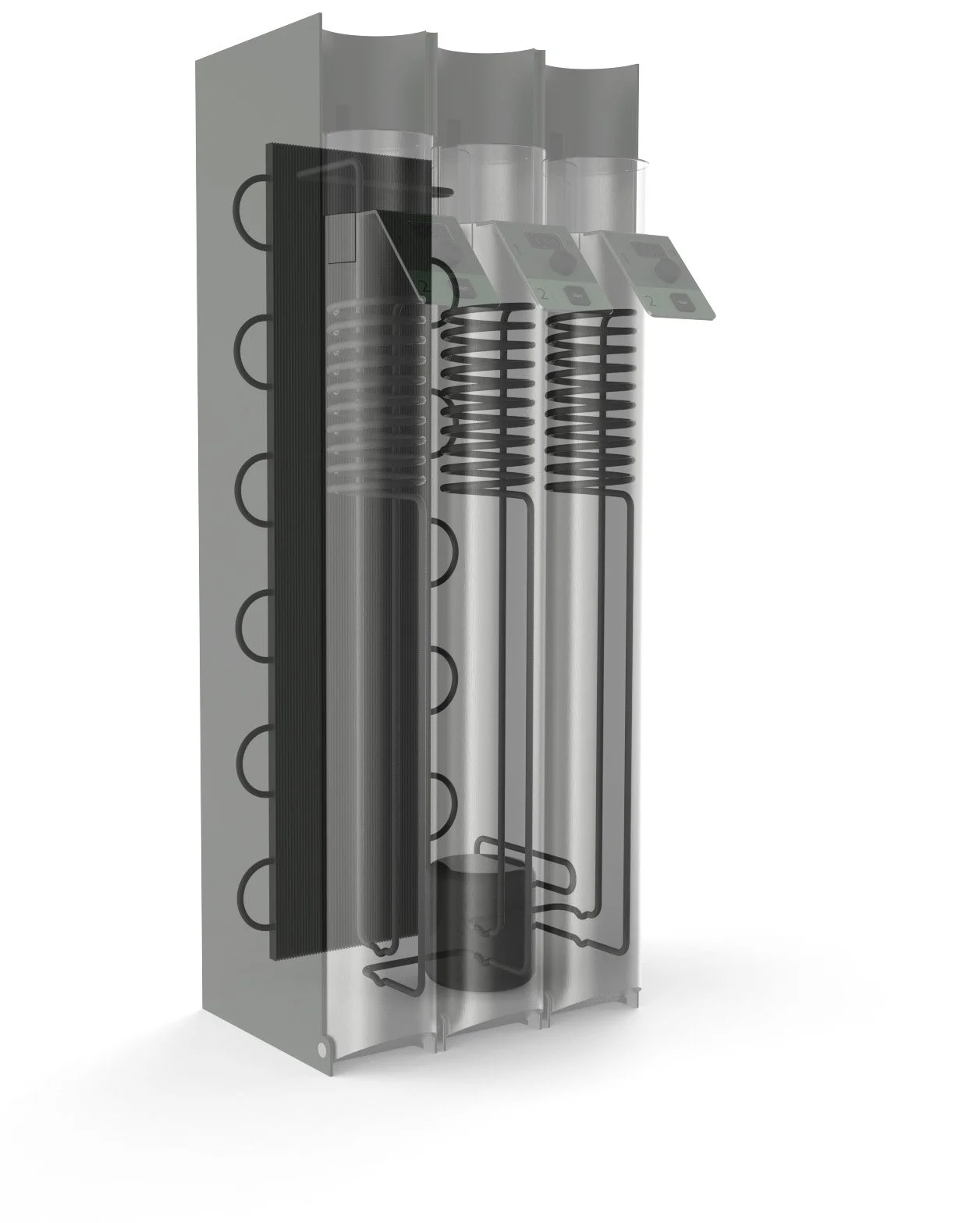

Three different types of food can be offered using the vending machine. To do this, there are three separate food containers in the device. After loading, the cylindrical containers are cooled to ensure food safety. For this purpose, the containers are surrounded by cooling elements connected to a compressor cooling system.

One container can hold approximately 3 kg of food.

The food containers are constructed in a way that allows them to be easily loaded and unloaded by one person. To do this, they can be tilted out of the device and removed upwards.

Food dispensing process

To dispense the food, it is pushed upwards into a dispensing area with a transparent cover over it. The cover allows the quantity of food to be seen while protecting it from contamination by shoppers. After the quantity of food has been defined and the dispensing process started, a dividing plate separates the desired amount of food. Additionally, the plate serves as a cover for the food supply stored in the vending machine. Once the dispensing process is complete, the cover opens and the food can be removed.

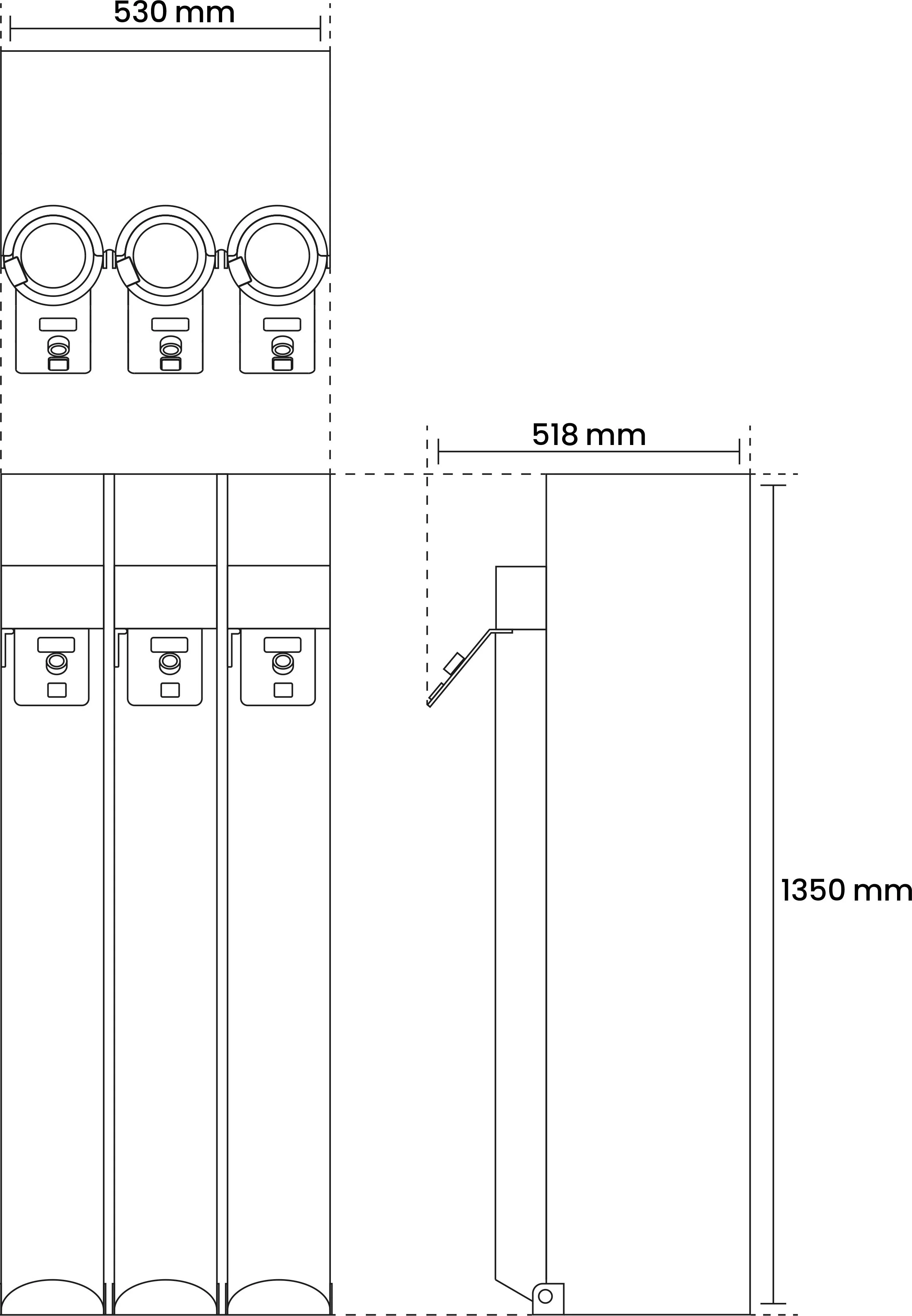

The vending machine is designed to take up only a small amount of floor space to ensure that it can also be used in smaller stores. Therefore, the components are arranged vertically, resulting in an upright, rectangular structure.

The concept is based on data collected through literature research, interviews, and surveys. This information was used to develop preliminary models.

Design process

To find the optimal layout and size of the interface, a user test was conducted. In this test, test persons had a choice between different shapes of control elements and their layout on a mock-up.

To ensure that the machine can be operated by as many people as possible, the layout of the controls are based on ergonomic percentiles in terms of visibility and reach. The design based on this data ensures that the device can be used by people with different ergonomic requirements.